VAWI Brand in-depth Unveiling: From Guangzhou Liwan to The Global Market

Protect·Personality·Green future

Founded in Guangzhou Liwan, VAWI has been adhering to this mission since 2012: to protect every mobile phone with innovative design and green materials, so that personality and environmental protection go hand in hand. This article reveals how VAWI has grown from a small workshop to a mobile phone case manufacturing company with a monthly output of 5 million pieces and sold to more than 30 countries and regions around the world from the aspects of brand birth, core values, production technology, product matrix, social responsibility and future planning.

Brand birth: the innovative dream in the small workshop in Liwan

Sora's return to China and the initial concept

In 2012, smart phones were rapidly popularized. Sora, who returned from studying abroad, was in Guangzhou and saw that the European and American markets’ demand for mobile phone cases that were “light, anti-fall, and environmentally friendly” had exceeded the basic protection function. However, the domestic market is generally homogenized, and it is rare to take into account both performance and aesthetics. To this end, Sora rented a factory of only 300 square meters in Guangzhou and co-founded VAWI with several like-minded partners. It is hoped that through technology and design upgrades, users will have a brand new experience.

Initial trials: a difficult and passionate proofing process

Initially, the VAWI team only had a few second-hand injection molding machines and hand-drawn drawings. During the day, they tested different TPU and PC ratios in the laboratory, and stayed up late at night to draw mobile phone case patterns and debug printing processes. After months of continuous experiments and improvements, in March 2013, the first batch of mobile phone cases with thermal transfer and UV printing processes were born. These products printed with illustrations and trendy patterns by European and American artists quickly received praise on cross-border e-commerce platforms such as Amazon and eBay. The annual export volume soon exceeded US$500,000, which also made the team firmly believe that “innovation and quality” are the foundation of the brand.

Mission and Vision: Make "protection" the most intimate companion for users

From "protecting the shell" to "guarding": comprehensively upgrading the user experience

For VAWI, “the essence of a mobile phone case is protection, but guarding is not just about preventing falls.” In 2014, the team built a small test laboratory in the factory workshop, carried out multiple rounds of verification on the honeycomb energy absorption structure, and finally developed the A3 honeycomb anti-fall structure. In the 1.8-meter drop test, the mobile phone case was almost intact, but still maintained a light and thin feel of 25-30 grams. At the same time, seeing that the environmental protection requirements of the European and American markets are becoming increasingly stringent. In 2018, VAWI launched the first generation of PLA + recycled polyester hybrid biodegradable mobile phone cases. Passed the composting and biodegradable tests of German TUV and SGS, and obtained the German Der Blaue Engel environmental certification, winning the brand the reputation of “green pioneer”.

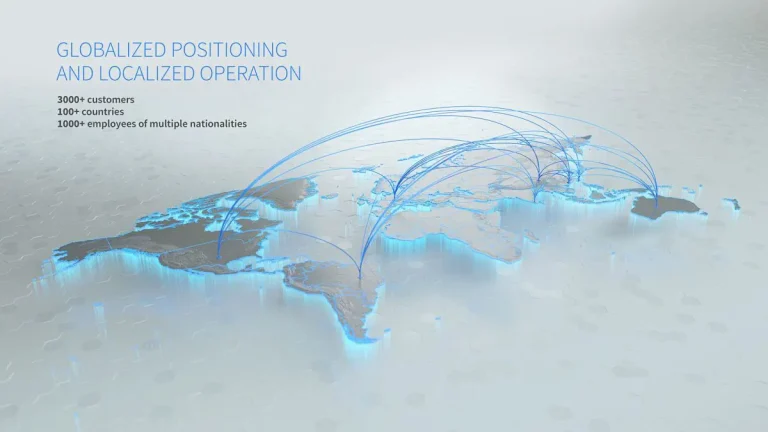

Global: Connect the world with "sharing wonderfulness"

“W (World)” is not just a letter, but also reflects VAWI’s ambition to go global. Since its first trip to the IFA exhibition in Berlin, Germany in 2015, VAWI’s honeycomb anti-fall and environmentally friendly series have attracted the attention of many buyers. In 2016, at the CES exhibition in the United States, the team brought magnetic brackets and degradable samples to the show, and obtained cooperation intentions from North American channels such as Best Buy and Target. In the following years, VAWI set up overseas warehouses in Los Angeles, Tokyo, Osaka, Japan, and even Santiago, Chile, to achieve “2-3 days delivery” localized logistics services. During the epidemic, relying on a stable overseas warehouse layout and localized supply chain, the export volume increased by 20% year-on-year against the trend. In 2020, VAWI proposed the slogan “Share Splendid With The World”. So far, it has exported to more than 30 countries and regions, and its annual export volume ranks among the top three in the industry.

Core Values: Finding a Balance between "Vision", "Action", "Innovation" and "Personality"

VAWI breaks down “V A W I” into six pairs of keywords, from vision, value to action, attitude, and then to the world, victory, innovation and personality, building the core of brand growth.

Vision and Value

Sora has set a long-term goal since its inception – to make VAWI the world’s leading mobile phone case brand and continue to meet user needs with technology and aesthetics. And “quality first” is the cornerstone of value. Passed ISO9001 quality management system certification in 2014. Obtained ISO14001 environmental management system certification in 2018. Ensure that from raw materials to processes to after-sales, high standards are met, and the product quality is always stable.

Action and Attitude

In technical projects, the team dares to transform production equipment and jointly tackles key problems with authoritative institutions such as Guangzhou Industrial Design Research Institute and the Chinese University of Hong Kong. It only takes a few weeks from the establishment of a new project to mass production, quickly responding to market demand. VAWI encourages employees to always respect the market, users, and quality, and holds “employee talk meetings” every month. Rational suggestions put forward by front-line workers can often be implemented in production and product iteration in a short time.

World and Win

“Going global” is the core of VAWI’s strategy: multilingual customer service, overseas warehouse layout, localized social media operation… This allows the brand to be quickly implemented in markets such as Europe, America, Japan, South Korea, Southeast Asia, the Middle East, and South America. The so-called “victory” is not only about rising sales, but also about winning the hearts of users. Many of VAWI’s products have been evaluated and recommended by media such as CNET, Wirecutter, and Stuff, and have won honors such as “China’s Excellent Foreign Trade Brand” and “Guangdong Province’s Excellent Export-oriented Enterprise”, which are all manifestations of “winning reputation and trust”.

Innovation and Individuality

More than 5% of turnover is invested in research and development every year, and a research and development and design team of more than 20 people has been established. Projects such as honeycomb anti-fall structure, biodegradable materials, magnetic brackets and smart NFC shells continue to bring surprises to the market. At the same time, VAWI emphasizes “personalized design”. It has launched limited series in collaboration with European, American, Japanese and Korean artists, and provides users with small batch OEM/ODM services with a minimum order of 500 pieces through fan customization and IP collaboration, so that the brand can always maintain its differentiated advantages in homogeneous competition.

Production and Technology: Rigorous Process and Intelligent Manufacturing in Parallel

VAWI’s factory is located in Dongguan, covering an area of 10,000 square meters and employing more than 500 people. In recent years, the factory has been continuously upgraded to intelligentization: from the initial few injection molding machines and manual proofing tables, it has gradually upgraded to a modern intelligent factory with 8 fully automatic high-speed injection molding and surface treatment production lines, 2 manual boutique lines, 4 robot automated assembly lines and supporting quality inspection laboratories.

Intelligent transformation: Towards Industry 4.0

- High-precision injection molding equipment: Introduce European imported injection molding machines to ensure accurate temperature control and injection pressure parameters, and control the shell size error within ±0.02mm.

- Online visual inspection system: The production line is equipped with AI defect recognition cameras to scan cracks, bubbles and color differences in real time. Defective products are immediately removed and data is recorded for subsequent process optimization.

- Automatic loading and unloading of robot arms: Robot arms are configured on multiple production lines to be responsible for melt and first inspection sorting. Humans are more involved in fine-tuning, texture evaluation and detail control, and production efficiency is increased by about 60%.

- MES+ERP system integration: The manufacturing execution system and the enterprise resource planning system are connected in real time to achieve digital and transparent management of the entire process from order placement, production scheduling to shipment.

- Automated packaging and intelligent warehousing: Qualified products enter the AGV automatic handling and sorting system after automatic vacuum compression packaging to ensure safety and efficiency during transportation.

These intelligent transformations not only greatly improved production capacity and quality, but also allowed VAWI to achieve breakthroughs in reducing energy consumption and reducing costs and increasing efficiency. Sora often said: “Intelligent production is our underlying logic, so that every kilowatt-hour of electricity and every drop of water are used to the best effect.”

Material and structure: dual-wheel driven technological innovation

Honeycomb anti-fall structure: taking into account both lightness and toughness

In 2016, VAWI cooperated with Guangzhou Industrial Design Research Institute and the Materials Science Research Center of the Chinese University of Hong Kong. Through repeated iterations of finite element simulation and 3D printing prototypes, the “six-sided honeycomb + double-layer wall glue” solution was finally determined. The shell remains intact after falling from six sides at a height of 1.8 meters, while maintaining a light weight of 25-30 grams. The structure has been tested and certified by UL (Underwriters Laboratories), and its impact resistance is increased by about 25% compared to structures of the same thickness, making it the first choice for users in outdoor sports and extreme scenes.

Degradable and environmentally friendly materials: technology and sustainable integration

In 2018, VAWI launched the degradable materials project and worked with the Guangzhou Industrial Design Institute and the Degradable Materials Laboratory of the Chinese University of Hong Kong. 18 months later, a PLA (polylactic acid) + recycled polyester hybrid material was developed. It can achieve impact resistance and high temperature resistance close to TPU, and can be naturally degraded in 4-6 months under a standard composting environment. After mass production in 2019, the material quickly became a hit in the environmental protection market in Japan and Europe. In 2024, VAWI carried out the second generation iteration on this basis. The material strength increased by 25% and the degradation cycle was shortened to 3-4 months, which once again consolidated the advantage of “green manufacturing”.

Magnetic multifunctional bracket: modular design practice

The “magnetic multifunctional bracket module” developed in cooperation with the Chinese University of Hong Kong and the American Magnetic Materials Laboratory consists of a high-strength NdFeB adsorption sheet and an aviation aluminum alloy bracket arm. The bracket can be locked at multiple angles of 0°-180° and is compatible with 90% of the on-board magnetic systems on the market. At a speed of 60km/h, the adsorption strength remains ≥90%. During small-scale trial production, the module underwent more than 5,000 magnetic cycle tests and 1,000 bump tests, and successfully passed the German TUV durability certification. After mass production in 2019, the magnetic case immediately topped Amazon’s US “Best Magnetic Case” bestseller list.

Product matrix: from basic protection to intelligent applications

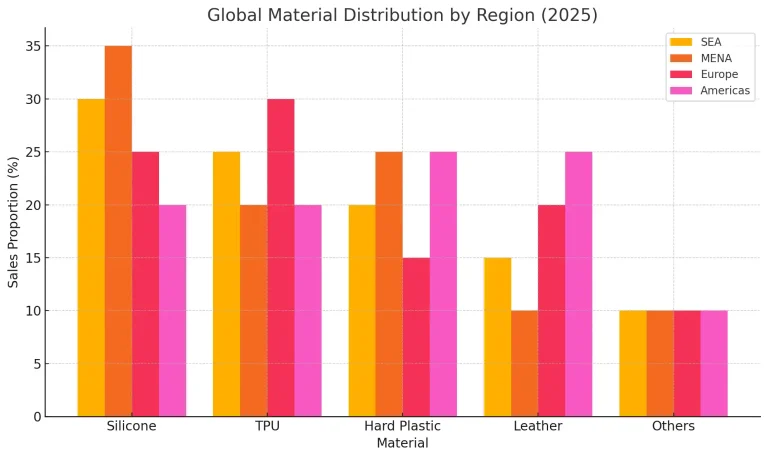

VAWI’s products cover multiple materials, multiple functions, and multiple styles to meet the diverse needs of different regions, different age groups, and different scenarios.

Multi-material series: meet the demands of feel and value

- PC hard shell: imported polycarbonate, combined with hot stamping, electroplating brushing and sandblasting, weighing 28-32 grams, taking into account business texture and durability.

- TPU soft shell: highly elastic thermoplastic polyurethane, combined with honeycomb structure, the impact resistance is increased by 25%, with rich colors and patterns, suitable for young groups and sports enthusiasts.

- Silicone soft shell: medical grade silicone, soft and skin-friendly. It has dustproof and anti-fingerprint functions, easy to clean, suitable for female and student users.

- Metal frame + PC/TPU back panel: aviation aluminum alloy or titanium alloy frame plus PC/TPU back panel. CNC processing and anodizing are used, with high-end appearance, suitable for business people.

- Leather/Fabric Series: Top cowhide, PU leather or high-quality fabric, combined with lining and card slot design, it is both beautiful and practical.

- Degradable and environmentally friendly series: Based on PLA + recycled polyester mixed formula, it is both shatter-resistant and degradable, meeting the needs of environmentalists.

Multifunctional series: Make the phone case no longer "single"

- Anti-fall and impact resistance: The honeycomb energy absorption structure is combined with the frame wrapping design. Through the multi-faceted drop test of UL and TUV institutions, it can remain intact after falling from six sides at a height of 1.8 meters.

- Magnetic multi-functional bracket: Modular design, the bracket can be locked at multiple angles. Compatible with 90% of the in-vehicle magnetic systems on the market, meeting the needs of in-vehicle navigation, home drama chasing and office video conferencing.

- Wireless charging compatible: All products have passed the Qi protocol transparent transmission test during the design stage, and wireless charging can be performed without removing the shell.

- Anti-scratch and anti-fingerprint: The surface uses nano-fluorine anti-fingerprint coating and anti-scratch coating to ensure that it is still as bright as new after daily use.

- Waterproof and dustproof: Optimize the design of sealing rubber ring and frame, provide basic protection against splashing water and dust environment in life, suitable for outdoor sports and travel scenes.

- Intelligent attempt: Cooperate with chip manufacturers to develop NFC-enabled mobile phone cases, explore the interaction between solar charging and low-power Bluetooth, and realize the functions of breathing light and message reminder for incoming calls.

Market and channel: Global layout and localization

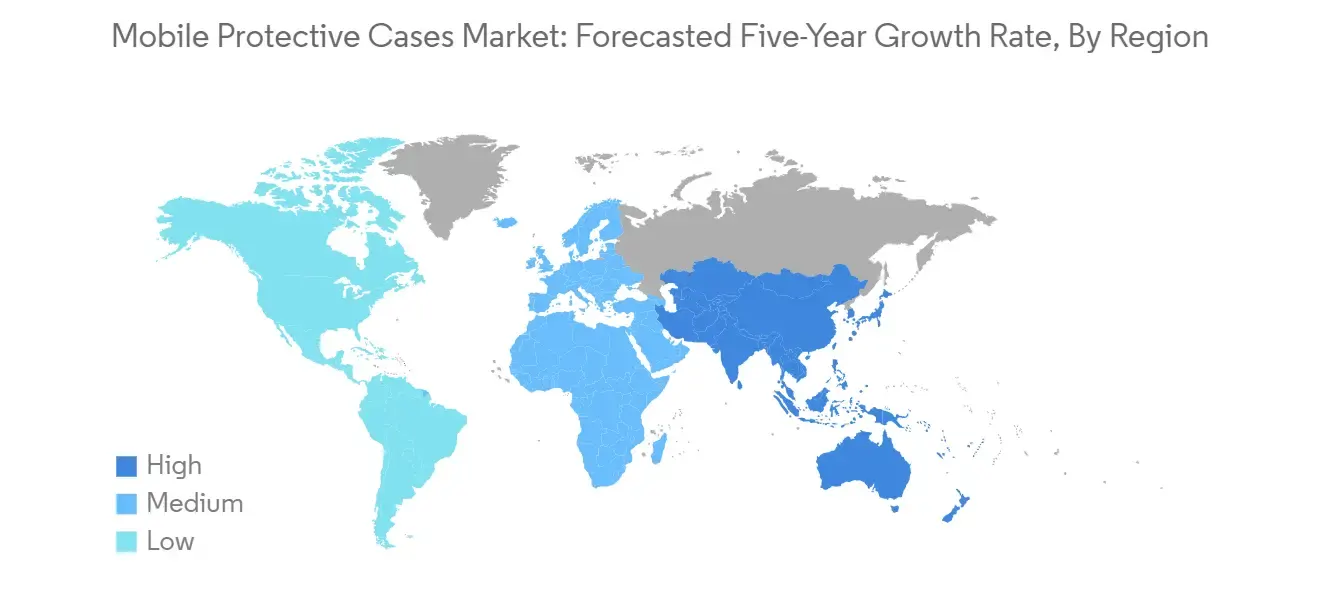

VAWI’s globalization strategy emphasizes “integrated layout + localized operation”, and establishes competitive barriers in various market segments with precise positioning and in-depth cooperation.

North America and Europe

In the North American market, VAWI has set up flagship stores through e-commerce platforms such as Amazon.com, eBay, and Walmart Marketplace. And cooperate with chain retailers such as Best Buy, Target, and GameStop to enable products to quickly reach consumers. At the same time, it has participated in CES and Retail’s BIG Show many times, and has received praise from authoritative evaluation media such as CNET and Wirecutter. In Europe, VAWI has obtained CE, RoHS, REACH, TUV and other certifications. It also cooperates with large chains such as MediaMarkt, Saturn, Fnac, and Currys, covering more than 500 offline stores. It has also won recognition from environmental organizations and the art circle by launching limited designs such as “Forest Watercolor” and “Green Graffiti” in collaboration with local artists.

South America

In Brazil, Argentina, Chile and other South American countries, VAWI quickly opened up the market with “cost-effective + localized design”. Online direct sales are achieved through mainstream e-commerce platforms such as Mercado Libre, OLX, and Linio. Cooperate with local distributors to display products in experience halls in Sao Paulo and Rio de Janeiro. During the 2022 World Cup, the “VAWI Brazil Edition” was launched, incorporating the colors of the Brazilian flag and football elements into the design, with monthly sales exceeding 50,000 pieces. At the same time, it cooperated with large department stores such as Falabella and Ripley to distribute goods to achieve full offline coverage.

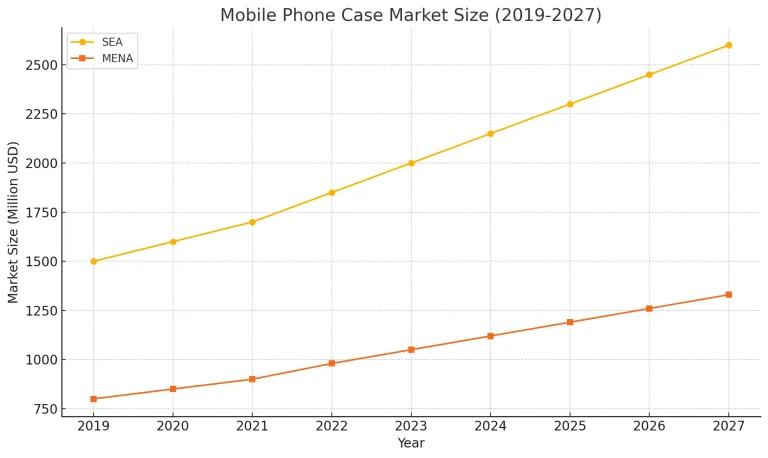

Southeast Asia

In Southeast Asian countries such as Thailand, Vietnam, Indonesia, and the Philippines, VAWI relies on key e-commerce platforms such as Shopee, Lazada, and Tokopedia. Combined with local influencers’ live broadcasts and holiday promotions, sales and brand awareness have been improved. The team launched localized patterns combining tropical flowers and cartoon animation. It also cooperated with offline supermarkets such as Central Department Store and Vincom Center to create an O2O experience. In 2022, the monthly live broadcast sales on Shopee exceeded 10,000 pieces, further consolidating its market position in Southeast Asia.

Middle East and North Africa

In the UAE, Saudi Arabia and Israel markets, VAWI’s high-end metal frame + leather stitching series meets the local dual needs for luxurious texture and practical functions. Through e-commerce platforms such as Amazon.ae, Noon.com, Namshi, and offline channels such as Sharaf DG, Jarir Bookstore, and Electra, the products have entered major supermarkets. The brand also launched limited editions of Arabic geometric patterns in conjunction with festivals such as Ramadan and Eid. Through multi-language live broadcasts and evaluations by local KOLs and bloggers, regional brand awareness has been greatly improved.

Australia and New Zealand

In Australia, VAWI’s biodegradable and environmentally friendly series and metal business series have entered the mainstream retail market through channels such as JB Hi-Fi and Officeworks. In addition, it cooperated with Planet Ark to launch the “Recycle Old Shells for Discounts” campaign, which attracted local attention. Through the Prime logistics services of eBay Australia and Amazon Australia, it achieved “2-4 days delivery” to meet the needs of fast delivery. In New Zealand, it cooperated with The Warehouse and Noel Leeming to make VAWI products cover major cities. Technology media such as Stuff.co.nz have repeatedly evaluated and recommended the brand, which has established the brand’s reputation in the local area.

Core Leadership: The joint drive of four leaders

The rapid rise of VAWI is inseparable from a passionate and innovative leadership team. The following is a brief introduction to the core leaders, showing how they work together to promote brand development:

Sora (Founder and Chairman)

Studied in electronics and mechanical engineering at the University of Applied Sciences Berlin in Germany, and was responsible for the European and American mobile phone accessories market. After returning to China, with a deep insight into technology and the market, he founded VAWI in Liwan, Guangzhou. From the initial manual proofing to today’s intelligent factory, Sora insists on “innovation and environmental protection in parallel”. He personally led the R&D team to overcome key technologies such as honeycomb anti-fall, degradable materials and magnetic brackets, and promoted the globalization of the brand.

Rudy (President)

Graduated from Sun Yat-sen University with a degree in business administration, he served as the supply chain director of a multinational manufacturing company. He joined VAWI in 2015 and led the team to expand the factory and intelligentize the transformation, increasing the production capacity from 1.5 million pieces/month to 5 million pieces/month. Rudy is well versed in lean production and cost control, and attaches great importance to green manufacturing and sustainable development. He led the introduction of photovoltaic power generation and exhaust gas purification systems to achieve a double reduction in energy consumption and emissions.

Amy (Head of the R&D Center)

Graduated from the Chinese Academy of Sciences with a major in materials science, he has a rich background in polymer materials and structural mechanics. The R&D team led by Amy worked together with the Guangzhou Industrial Design Institute and the Chinese University of Hong Kong. The development of honeycomb anti-fall, degradable materials and magnetic bracket modules has been completed. She emphasizes “technology drives innovation” and leads the team to continuously break through the boundaries of materials and structures, providing solid guarantees for VAWI’s product performance.

KK (Marketing and Design Director)

With a dual background in marketing at Fudan University and industrial design at Guangzhou Academy of Fine Arts, KK has unique advantages in market insight and design creativity. As design director, he led the team to win the European Environmental Design Award and the German Red Dot Design Award nomination for three consecutive years. At the same time, as the head of marketing, he led the global marketing strategy. Collaborating with KOLs and Internet celebrities from all over the world, through localized activities and trendy joint names, he successfully promoted the VAWI brand to the world.

Social Responsibility and Sustainable Development: Practicing Green and Public Welfare

VAWI has always practiced the concept of “corporate development is social responsibility” and promoted sustainable development with environmentally friendly manufacturing and public welfare actions.

Environmentally friendly manufacturing: full-chain carbon reduction and circular economy

Green supply chain:

VAWI gives priority to suppliers that have passed the ISO14001 environmental management system certification. All plastic particles, additives and dyes must comply with EU RoHS and REACH standards.

Degradable materials:

Leading the development of PLA + recycled polyester mixed materials, the mobile phone case will be naturally degraded in 4-6 months under a standard composting environment. The second-generation formula will be launched in 2024, with a 25% increase in material strength and a shortened degradation cycle of 3-4 months.

Production process control:

VOC waste gas recovery and purification equipment is installed in the factory, and the three-level wastewater treatment system reuses wastewater. The lighting is fully upgraded to LED, and the injection molding and surface treatment equipment are equipped with variable frequency energy-saving control devices, with an average annual energy consumption reduction of 12%.

Circular economy model:

In 2022, the “Old Shell Recycling Plan” will be launched, and more than 50 recycling points will be set up across the country and overseas, with more than 85% of recycled materials being recycled. The packaging design uses FSC-certified paper and bio-based degradable filling bags, reducing the overall plastic usage by 30%.

Carbon neutrality vision:

Install a 200kW photovoltaic power generation system on the roof of the Guangzhou Liwan factory in 2024. Gradually replace forklifts and transporters with electric versions. Cooperate with the Climate and Environmental Research Center of Sun Yat-sen University and the Dongguan Meteorological Bureau to establish a “Carbon Capture Laboratory”, aiming to achieve carbon neutrality in the production process by 2030.

Charity Action: Education Aid and Emergency Rescue

VAWI Student Aid Fund:

Since its launch in 2021, it has donated 500,000 yuan in scholarships to schools in poor areas such as Huaihua, Hunan and Qiandongnan, Guizhou every year, and donated computers and books. In 2023, Sora and team members went to Datang Primary School in Guizhou to carry out the “VAWI Technology and Art” summer camp, bringing programming and art courses to more than 300 students.

Community Environmental Protection Promotion:

In 2022, jointly with the Qiaozhong Sub-district Office of Liwan District and the Guangzhou Environmental Protection Bureau, a “Green Manufacturing · Low-carbon Life” Promotion Week was held in the Liwan Community. Through the waste mobile phone case recycling exhibition, environmental protection workshops and volunteer lectures, the community participated in more than 2,000 people.

Emergency disaster relief:

During the flood disaster in Zhengzhou, Henan in 2021, the Red Cross Society of Henan Province donated 300,000 yuan in supplies and donations, and sent a volunteer team to assist in the rescue. During the same period, during the flood disaster in Bangladesh, the Red Crescent Society of Bangladesh donated cash and first aid supplies, and carried out the “Old Shell for Rescue Kit” activity in Dhaka. During the Kyushu typhoon in 2019, the Japanese Red Cross donated 200,000 yen, and launched similar circular economy charity activities in Fukuoka and Kumamoto.

Future Outlook: Intelligence, Globalization and Circularization

In the next five years, VAWI will promote the continuous upgrading of brands and products around the four key words of “intelligence, globalization, greening and circularization”.

Intelligence and digitalization: moving towards comprehensive upgrading

Automation expansion:

On the basis of the existing automated production line, more robot loading and unloading systems and automatic quality inspection and rejection equipment are added to achieve 24-hour unattended production.

MES + ERP deep integration:

open up the data interface between ERP, MES and production line equipment, build a “production brain”, and realize production scheduling optimization and predictive maintenance through big data algorithms.

Digital design platform:

launch the “cloud collaborative design” system, incorporate user data, social media feedback and after-sales evaluation into design iteration, and shorten the cycle from concept to mass production of new products to less than 30 days.

3D printing + flexible production:

use 3D printing to quickly make molds, combined with automated flexible production lines, to provide B2B customers with more flexible and diverse small batch customization services.

Globalization and localization: making "sharing excitement" a reality

Overseas warehouse network expansion:

Based on the existing overseas warehouses in the United States, Europe, Japan, etc., 5-8 overseas warehouses will be added by 2025, covering Mexico, Brazil, Saudi Arabia, Israel, Singapore, Indonesia and other regions, to achieve “2-4 days arrival” and “localized return and exchange” services.

Localized marketing strategy:

- European and American markets emphasize “high-end design + environmental protection concept”, cooperate with local YouTubers and Instagram technology bloggers to launch limited joint models.

- Southeast Asian market focuses on “cost-effectiveness + trend interaction”, and cooperates with local top anchors to bring goods on Shopee Live and Lazada Liveshow.

- The Middle East market highlights “luxury texture + practical functions”, launches customized promotions during Ramadan and Eid, and cooperates with local fashion bloggers.

- The Latin American market focuses on “football culture + local patterns”, and cooperates with local sports media to promote in conjunction with major events such as the World Cup.

Offline experience and cross-border cooperation:

plans to open 3-5 experience stores in trendy landmarks such as New York Times Square, London Oxford Street, Tokyo Shibuya, Sydney Darling Harbor, etc., combining “mobile phone case + interactive experience + art exhibition”. And launch “VAWI × Art” theme activities with cafes, art exhibitions, and pop-up stores to enhance brand popularity through limited joint ventures and interactive installations.

Product matrix diversification: from mobile phone cases to smart accessories ecosystem

Smart functional shell:

cooperate with chip and sensor manufacturers to launch smart shells with built-in NFC and low-power Bluetooth. Realize multi-functions such as access cards, bus cards, and car unlocking. Develop solar charging shells, combining honeycomb structures with foldable solar panels to provide emergency power for outdoor users. Plans to launch a prototype “smart protective shell” in 2025, which can detect mobile phone falls and automatically trigger SOS distress signals.

Green degradable series:

Continuously optimize degradable formulas, aiming to achieve “standard degradable” for the entire series in 2026. Cooperate with marine environmental protection organizations to develop “marine plastic recycling + degradable composite materials” and launch the “pick up shells for discounts” public welfare activities in coastal communities.

Accessory ecosystem expansion:

Extend from mobile phone cases to wireless charging bases, magnetic brackets, data cables, tempered films, Bluetooth selfie sticks and other smart accessories. Form a one-stop solution for “mobile phone cases + accessories”. Plan to enter the smart bracelet, tablet computer protective case and other digital accessories market by the end of 2026 to build a complete digital peripheral ecosystem.

Sustainable development and social responsibility upgrade

Carbon neutrality roadmap:

formulate a “carbon emission monitoring and control” plan and introduce more solar and wind power generation facilities. Promote electric logistics fleets and new energy equipment to reduce traditional fuel emissions. Cooperate with Sun Yat-sen University Climate and Environmental Research Center and Dongguan Meteorological Bureau. Improve the “Carbon Capture Laboratory” project and strive to achieve carbon neutrality in the production process by 2030.

Circular economy and public welfare cultivation:

Set up more than 100 “old shell recycling points” worldwide to improve the recycling network and resource reuse system. Upgrade the “VAWI Student Aid Fund” to the “VAWI Charity Foundation”. Fund 100 children in poor areas every year, and expand to the fields of vocational education and skills training. Regularly carry out “VAWI Green Charity Tour” activities around the world, organize tree planting, beach cleaning and environmental protection classes, and form a lasting social influence.

Contact information and visit invitation

VAWI firmly believes that “openness, cooperation and sharing” is the only way for enterprises to go higher and further. We sincerely invite global partners, customers and media friends to join us in protecting every mobile phone with innovation and quality. Accompany every user with art and environmental protection, and light up every corner of the world with passion and vitality.

Factory address: VAWI Industrial Park, Hengli Town, Dongguan City

Office address: North Tower, Xijiao Commercial Center, Qiaozhong Road, Liwan District, Guangzhou City

Tel: +86-136 6004 0341

Email: Joyporodo@gmail.com

- Public consultation: Joyporodo1@163.com

- OEM/ODM customization: factorysale01@joyporodo.com

- After-sales and technical support: postmaster@joyporodo.com

Online customer service: Click “Online Consultation” in the lower right corner of the official website to support English, German, Spanish, French, Japanese, Arabic and other languages

Official website: www.vawicase.com

Social media:

- Facebook: www.facebook.com/vawicase

- Instagram: www.instagram.com/vawi_case

Visit instructions

- Appointment method: Please make an appointment at least 7 working days in advance through the official website online form or send an email to Joyporodo@gmail.com Make an appointment and state the number of people in the group and the purpose of the visit.

- Safety Tips: Visitors must wear the safety helmets and safety shoes provided by the factory; flash photography is prohibited in the production area. If you need to take photos of the process flow, please obtain authorization from the factory manager in advance.

- Visiting time: Monday to Friday 9:00-17:00 (except statutory holidays). Please contact in advance if you need to visit on weekends.

Conclusion: Make "protection" and "sharing" every possible

From a small workshop of 300 square meters and a few second-hand injection molding machines in Liwan District in 2012 to a modern smart factory of 10,000 square meters, a monthly output of 5 million pieces, and sales to more than 30 countries and regions around the world. VAWI has used more than ten years to prove that as long as you have the dream of innovation and insist on quality and environmental protection, there is no hurdle that you can’t overcome and no road that you can’t go far.

In the future, VAWI will continue to take “Protection·Personality·Green Future” as its brand concept:

- Protection: Provide ultimate protection for mobile phones based on lighter, thinner and stronger materials and structures;

- Personality: Integrate trendy elements, artistic design and diversified customization, so that every user can find the “unique” one;

- Green Future: Continue to promote the construction of degradable materials and circular economy system, strive to make products no longer a burden on the environment after use, and let environmental protection and technology go hand in hand.

“Share Splendid With The World” is not an empty slogan, but VAWI’s solemn promise to global users! Let innovation and quality, art and environmental protection truly become “shared wealth” that everyone can easily enjoy. On this road, VAWI hopes to work hand in hand with you to jointly open a brighter new era of mobile digital.

VAWI-protect the safety of every mobile phone and achieve every wonderful experience.